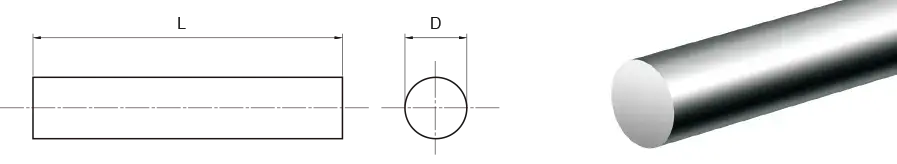

Solid Rods

Solid carbide rods in various grades and sizes

►The ideal grade for various application

Our creative grade range satisfies each demand of the modern precision tooling industry. You can find the specific grade for all work-piece-material or application.

►Acknowledged quality

Our solid carbide rods are renowned as their high performance and constant quality. Our stability is the cornerstone of your cutting tool performance.

►Extensive product portfolio available in stock

Our program offers you a wide range of dimensions, features and capabilities. In addition, fast and safe delivery service will be your back-up for all time.

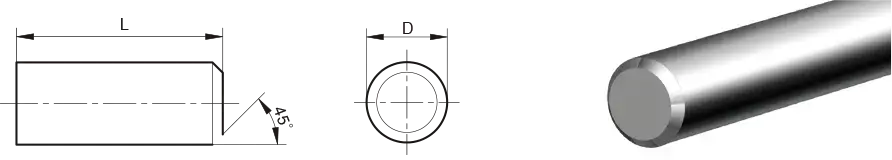

Sintered Solid Rods (Metric)

| Sintered Solid Rods (Metric) | |||||||||

| Code | D | L | Grade | ||||||

| mm | mm | K180 | UF25 | WF25 | KS09 | WF15 | K200 | K100L | |

| RR 0220−330 | 2.0 | 330 | ● | ● | ● | ||||

| RR 0320−330 | 3.0 | 330 | ● | ● | ● | ● | ● | ● | |

| RR 0370−330 | 3.5 | 330 | ● | ● | ● | ||||

| RR 0420−330 | 4.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 0470−330 | 4.5 | 330 | ● | ● | ● | ||||

| RR 0520−330 | 5.0 | 330 | ● | ● | ● | ● | |||

| RR 0570−330 | 5.5 | 330 | ● | ● | ● | ||||

| RR 0620−330 | 6.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 0670−330 | 6.5 | 330 | ● | ● | ● | ||||

| RR 0720−330 | 7.0 | 330 | ● | ● | ● | ||||

| RR 0770−330 | 7.5 | 330 | ● | ● | ● | ||||

| RR 0820−330 | 8.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 0870−330 | 8.5 | 330 | ● | ● | ● | ||||

| RR 0920−330 | 9.0 | 330 | ● | ● | ● | ||||

| RR 0970−330 | 9.5 | 330 | ● | ● | ● | ||||

| RR 1020−330 | 10.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 1070−330 | 10.5 | 330 | ● | ● | ● | ||||

| RR 1120−330 | 11.0 | 330 | ● | ● | ● | ||||

| RR 1170−330 | 11.5 | 330 | ● | ● | ● | ||||

| RR 1220−330 | 12.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 1270−330 | 12.5 | 330 | ● | ● | ● | ||||

| RR 1320−330 | 13.0 | 330 | ● | ● | ● | ||||

| RR 1420−330 | 14.0 | 330 | ● | ● | ● | ● | |||

| RR 1520−330 | 15.0 | 330 | ● | ● | ● | ||||

| RR 1620−330 | 16.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 1720−330 | 17.0 | 330 | ● | ● | ● | ||||

| RR 1820−330 | 18.0 | 330 | ● | ● | ● | ● | ● | ● | |

| RR 1920−330 | 19.0 | 330 | ● | ● | ● | ||||

| RR 2020−330 | 20.0 | 330 | ● | ● | ● | ● | ● | ● | ● |

| RR 2420−330 | 24.0 | 330 | ● | ● | |||||

| RR 2520−330 | 25.0 | 330 | ● | ● | |||||

| RR 3220−330 | 32.0 | 330 | ● | ● | |||||

● = Standard Stock

1. Standard Diameter: Ø2 ~ Ø32, other dimensions are upon request.2. Standard Length: 310 / 330 mm.

We offer below post-processing services:

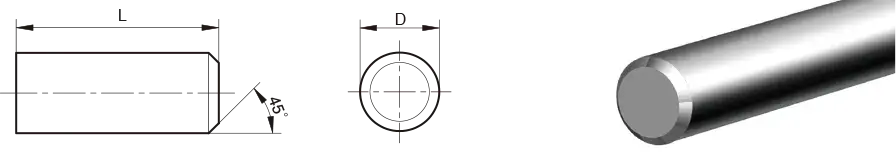

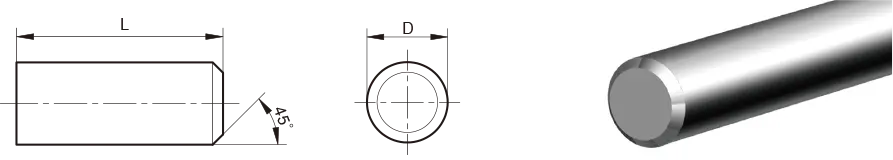

Ground Solid Rods - Cut to Length (Metric)

| Ground Solid Rods - Cut to Length (Metric) | ||||||||||

| Code | D | h5 D Tol. | L | Chamfer | Grade | |||||

| mm | mm | mm | mm | K180 | UF25 | WF25 | KS09 | WF15 | K200 | |

| RGMC 0300-050 | 3.0 | -0/-0.004 | 50 | 0.3 | ● | ● | ● | ● | ||

| RGMC 0400-050 | 4.0 | -0/-0.005 | 50 | 0.4 | ● | ● | ● | ● | ● | ● |

| RGMC 0400-075 | 4.0 | -0/-0.005 | 75 | 0.4 | ● | ● | ||||

| RGMC 0400-100 | 4.0 | -0/-0.005 | 100 | 0.4 | ● | |||||

| RGMC 0600-050 | 6.0 | -0/-0.005 | 50 | 0.6 | ● | ● | ● | ● | ● | ● |

| RGMC 0600-075 | 6.0 | -0/-0.005 | 75 | 0.6 | ● | |||||

| RGMC 0600-100 | 6.0 | -0/-0.005 | 100 | 0.6 | ● | ● | ||||

| RGMC 0800-060 | 8.0 | -0/-0.006 | 60 | 0.8 | ● | ● | ● | ● | ● | |

| RGMC 0800-075 | 8.0 | -0/-0.006 | 75 | 0.8 | ● | |||||

| RGMC 0800-100 | 8.0 | -0/-0.006 | 100 | 0.8 | ● | ● | ||||

| RGMC 1000-075 | 10.0 | -0/-0.006 | 75 | 1.0 | ● | ● | ● | ● | ● | ● |

| RGMC 1000-100 | 10.0 | -0/-0.006 | 100 | 1.0 | ● | ● | ||||

| RGMC 1000-150 | 10.0 | -0/-0.006 | 150 | 1.0 | ● | |||||

| RGMC 1200-075 | 12.0 | -0/-0.008 | 75 | 1.0 | ● | ● | ● | ● | ● | ● |

| RGMC 1200-100 | 12.0 | -0/-0.008 | 100 | 1.0 | ● | ● | ||||

| RGMC 1200-150 | 12.0 | -0/-0.008 | 150 | 1.0 | ● | |||||

| RGMC 1600-100 | 16.0 | -0/-0.008 | 100 | 1.0 | ● | ● | ● | ● | ● | ● |

| RGMC 1600-150 | 16.0 | -0/-0.008 | 150 | 1.0 | ● | ● | ● | |||

| RGMC 2000-100 | 20.0 | -0/-0.009 | 100 | 1.5 | ● | ● | ● | |||

| RGMC 2000-150 | 20.0 | -0/-0.009 | 150 | 1.5 | ● | ● | ● | |||

● = Standard Stock

1. Standard Diameter: Ø3 ~ Ø20, other dimensions are upon request.2. Standard Length: Metric standard, other dimensions are upon requst.

We offer below post-processing services:

Ground Solid Rods - Cut to Length (DIN)

| Ground Solid Rods - Cut to Length (DIN) | |||||

| Code | D | h5 D Tol. | L | Chamfer | Grade |

| mm | mm | mm | mm | WF15 | |

| RGMC 0300−039 | 3.0 | -0/-0.004 | 39 | 0.3 | ○ |

| RGMC 0400−051 | 4.0 | -0/-0.005 | 51 | 0.4 | ○ |

| RGMC 0500−051 | 5.0 | -0/-0.005 | 51 | 0.5 | ○ |

| RGMC 0600−051 | 6.0 | -0/-0.005 | 51 | 0.6 | ○ |

| RGMC 0600−055 | 6.0 | -0/-0.005 | 55 | 0.6 | ○ |

| RGMC 0600−058 | 6.0 | -0/-0.005 | 58 | 0.6 | ○ |

| RGMC 0800−059 | 8.0 | -0/-0.006 | 59 | 0.8 | ○ |

| RGMC 0800−064 | 8.0 | -0/-0.006 | 64 | 64 | ○ |

| RGMC 1000−067 | 10.0 | -0/-0.006 | 67 | 1.0 | ○ |

| RGMC 1000−073 | 10.0 | -0/-0.006 | 73 | 1.0 | ○ |

| RGMC 1200−074 | 12.0 | -0/-0.008 | 74 | 1.0 | ○ |

| RGMC 1200−084 | 12.0 | -0/-0.008 | 84 | 1.0 | ○ |

| RGMC 1400−076 | 14.0 | -0/-0.008 | 76 | 1.0 | ○ |

| RGMC 1400−084 | 14.0 | -0/-0.008 | 84 | 1.0 | ○ |

| RGMC 1600−083 | 16.0 | -0/-0.008 | 83 | 1.0 | ○ |

| RGMC 1600−093 | 16.0 | -0/-0.008 | 93 | 1.0 | ○ |

| RGMC 1800−093 | 18.0 | -0/-0.008 | 93 | 1.5 | ○ |

| RGMC 2000−093 | 20.0 | -0/-0.009 | 93 | 1.5 | ○ |

| RGMC 2000−105 | 20.0 | -0/-0.009 | 105 | 1.5 | ○ |

○ = Make-to-Order

1. Standard Diameter: Ø3 ~ Ø20, other dimensions are upon request.2. Standard Length: DIN standard, other dimensions are upon requst.

We offer below post-processing services:

Ground Solid Rods - Cut to Length (Inch)

| Ground Solid Rods - Cut to Length (Inch) | |||||||

| Code | D | h6 D Tol. | L | Chamfer | Grade | ||

| inch | mm | mm | inch | mm | mm | K200 | |

| RGIC 1/8−1 1/2 | 1/8 | 3.175 | -0/-0.008 | 1 1/2 | 38.10 | 0.4 | ○ |

| RGIC 1/8−2 | 1/8 | 3.175 | -0/-0.008 | 2 | 50.80 | 0.4 | ○ |

| RGIC 1/8−2 1/2 | 1/8 | 3.175 | -0/-0.008 | 1 1/2 | 63.50 | 0.4 | ○ |

| RGIC 3/16−2 | 3/16 | 4.763 | -0/-0.008 | 2 | 50.80 | 0.4 | ○ |

| RGIC 3/16−2 1/2 | 3/16 | 4.763 | -0/-0.008 | 2 1/2 | 63.50 | 0.4 | ○ |

| RGIC 3/16−3 | 3/16 | 4.763 | -0/-0.008 | 3 | 76.20 | 0.4 | ○ |

| RGIC 1/4−2 | 1/4 | 6.350 | -0/-0.009 | 2 | 50.80 | 0.4 | ○ |

| RGIC 1/4−2 1/2 | 1/4 | 6.350 | -0/-0.009 | 2 1/2 | 63.50 | 0.4 | ○ |

| RGIC 1/4−3 | 1/4 | 6.350 | -0/-0.009 | 3 | 76.20 | 0.4 | ○ |

| RGIC 5/16−2 1/2 | 5/16 | 7.938 | -0/-0.009 | 2 1/2 | 63.50 | 0.6 | ○ |

| RGIC 5/16−3 | 5/16 | 7.938 | -0/-0.009 | 3 | 76.20 | 0.6 | ○ |

| RGIC 5/16−3 1/2 | 5/16 | 7.938 | -0/-0.009 | 3 1/2 | 88.90 | 0.6 | ○ |

| RGIC 5/16−4 | 5/16 | 7.938 | -0/-0.009 | 4 | 101.60 | 0.6 | ○ |

| RGIC 3/8−2 1/2 | 3/8 | 9.525 | -0/-0.009 | 2 1/2 | 63.50 | 0.6 | ○ |

| RGIC 3/8−3 | 3/8 | 9.525 | -0/-0.009 | 3 | 76.20 | 0.6 | ○ |

| RGIC 3/8−3 1/2 | 3/8 | 9.525 | -0/-0.009 | 3 1/2 | 88.90 | 0.6 | ○ |

| RGIC 3/8−4 | 3/8 | 9.525 | -0/-0.009 | 4 | 101.60 | 0.6 | ○ |

| RGIC 7/16−2 3/4 | 7/16 | 11.113 | -0/-0.011 | 2 3/4 | 69.85 | 0.6 | ○ |

| RGIC 1/2−3 | 1/2 | 12.700 | -0/-0.011 | 3 | 76.20 | 0.8 | ○ |

| RGIC 1/2−3 1/2 | 1/2 | 12.700 | -0/-0.011 | 3 1/2 | 88.90 | 0.8 | ○ |

| RGIC 1/2−4 | 1/2 | 12.700 | -0/-0.011 | 4 | 101.60 | 0.8 | ○ |

| RGIC 1/2−5 | 1/2 | 12.700 | -0/-0.011 | 5 | 127.00 | 0.8 | ○ |

| RGIC 5/8−3 1/2 | 5/8 | 15.875 | -0/-0.011 | 3 1/2 | 88.90 | 1.0 | ○ |

| RGIC 5/8−4 | 5/8 | 15.875 | -0/-0.011 | 4 | 101.60 | 1.0 | ○ |

| RGIC 5/8−5 | 5/8 | 15.875 | -0/-0.011 | 5 | 127.00 | 1.0 | ○ |

| RGIC 5/8−6 | 5/8 | 15.875 | -0/-0.011 | 6 | 152.40 | 1.0 | ○ |

| RGIC 3/4−4 | 3/4 | 19.050 | -0/-0.013 | 4 | 101.60 | 1.0 | ○ |

| RGIC 3/4−5 | 3/4 | 19.050 | -0/-0.013 | 5 | 127.00 | 1.0 | ○ |

| RGIC 3/4−6 | 3/4 | 19.050 | -0/-0.013 | 6 | 152.40 | 1.0 | ○ |

| RGIC 3/4−7 | 3/4 | 19.050 | -0/-0.013 | 7 | 177.80 | 1.0 | ○ |

| RGIC 1 −4 | 1 | 25.400 | -0/-0.013 | 4 | 101.60 | 1.0 | ○ |

| RGIC 1 −5 | 1 | 25.400 | -0/-0.013 | 5 | 127.00 | 1.0 | ○ |

| RGIC 1 −6 | 1 | 25.400 | -0/-0.013 | 6 | 152.40 | 1.0 | ○ |

| RGIC 1 −7 | 1 | 25.400 | -0/-0.013 | 7 | 177.80 | 1.0 | ○ |

| RGIC 1 −8 | 1 | 25.400 | -0/-0.013 | 8 | 203.20 | 1.0 | ○ |

● = Standard Stock

○ = Make-to-Order

1. Standard Diameter: Ø1/8" ~ Ø 1", other dimensions are upon request.○ = Make-to-Order

2. Standard Length: Imperial standard, other dimensions are upon requst.

We offer below post-processing services:

For the production of high-quality solid carbide tools such as milling cutters, drills or reamers.

Our grade range covers the ISO application range K05 to K40, from machining carbon steel through to composite materials, non-ferrous metals and on to the demanding requirements of heat-resistant alloys.

Special grades for diamond coating complete our range of products.

Our grade range covers the ISO application range K05 to K40, from machining carbon steel through to composite materials, non-ferrous metals and on to the demanding requirements of heat-resistant alloys.

Special grades for diamond coating complete our range of products.