Gear Hobs

Ultra high precision, excellent hobbing performance

Our hobs prove themselves by their enormously long tool life and are thus also capable of extremely productive applications: in comparison with powder-metallurgical steels, carbide hobs can be driven with considerably higher cutting speeds – resulting in drastically lower machining times and ultimately greater economy in the entire process. We are flexible to meet customer tailored need. The breakthrough of soonest 10 days delivery time, it absolutely adapts the high speed development of HSS transferring to carbide material.

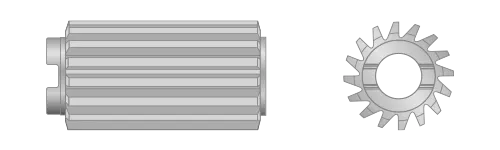

Blank products

◆ With products

◆ With hole

◆ With or without drive siot

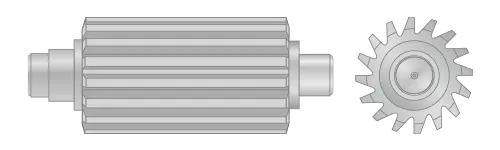

◆ With products

◆ With hole

◆ With or without drive siot

Carbide properties

◆ Wear resistance

◆ Fracture toughness

◆ Compressive strength

◆ Coatability

◆ Rigidity

◆ Wear resistance

◆ Fracture toughness

◆ Compressive strength

◆ Coatability

◆ Rigidity

|

|

|

| Grade | ISO code(s) |

Co (±0.5%) |

Grain Size | Density (g/cm3)±0.1 |

Hardness (HRA)±0.5 |

Area of application | ||

|

K05 | 8 | Ultrafine | 14.48 | 93.5 | Hard hobbing >55HRC | ||

|

K05 | 12 | Ultrafine | 14.10 | 92.4 | Hard hobbing >55HRC | ||

|

K10-K20 | 11 | Ultrafine | 14.15 | 92.3 | Soft hobbing up to 55HRC | ||

|

K10-K20 | 11.5 | Ultrafine | 14.15 | 92.2 | Soft hobbing up to 55HRC | ||

|

K20-K30 | 10 | Submicron | 14.35 | 91.8 | Soft hobbing up to 35HRC | ||

|

K20-K30 | 10 | Submicron | 14.40 | 91.5 | Soft hobbing up to 35HRC |

● Sectors, applications:

○ Automotive industry

○ Reduction gearbox

○ Motorcycle

○ Electrical power tool

○ Steering pinion

○ Engine

● Sectors, applications:

○ Steel

○ Non Ferrous metals

○ Composite materials

○ Automotive industry

○ Reduction gearbox

○ Motorcycle

○ Electrical power tool

○ Steering pinion

○ Engine

● Sectors, applications:

○ Steel

○ Non Ferrous metals

○ Composite materials