Tungsten Carbide Grade

Leader of high-end cutting tool

CB-CERATIZIT has long been forcusing on tungsten carbide production. We are capable of deliverying high quality, stable, and sepcialised carbide grade to cope with fast-changing market demands. Tungsten carbide products from CB-CERATIZIT are widly applied in every territory, such as Aerospace, Automotive, Electronic, and Medical industry.

In order to build up a professional knowledge platform, Tianjin Tooling Academy was set up in 2011. It is aimed to integrate European & Asian technology and to coach staff to become cutting tool solution experts. Through this platform, CB-CERATIZIT is able to consolidate material resource and industrial knowledge service.

Composition & Property

| Grade | ISO Code | Co(±0.5%) | Density(g/cm3) | Hardness | TRS(MPa) | |||

| HRA | HV30 | |||||||

| Ultrafine | ||||||||

| K180 | K05-K10 | 9.0 | 14.34 | 93.8 | 1,970 | 3,600 | ||

| UF25 | K10 - K20 | 12.0 | 14.10 | 92.4 | 1,680 | 4,000 | ||

| WF25 | K10-K20 | 11.5 | 14.15 | 92.2 | 1,650 | 3,800 | ||

| Submicron | ||||||||

| KS09 | K20-K40 | 9.0 | 14.48 | 91.8 | 1,580 | 3,600 | ||

| WF15 | K20-K40 | 10.0 | 14.35 | 91.8 | 1,580 | 3,800 | ||

| K200 | K20-K40 | 10.0 | 14.40 | 91.3 | 1510 | 4,000 | ||

| Fine | ||||||||

| K100L | K10-K20 | 6.0 | 14.83 | 92.2 | 1,650 | 3,000 | ||

| KR10 | K10-K20 | 5.8 | 14.80 | 92.2 | 1,650 | 3,000 | ||

Grade Property & Recommendation

|

Ultrafine grain

K180 :

Ultrafine grade for HSC machining of tempered steel (HRC>60), abrasive aluminium, or CFRP.

UF25 :

Ultrafine grade for HSC machining of tempered steel (HRC≤60) and stainless steel. Even more concentrated grain distribution enhances tool life and work performance.

WF25 :

Appropriate for machining tempered steel (HRC<45) and stainless steel. It is a well-balanced high performance grade.

|

Submicron grain

KS09 :

Appropriate for machining stainless steels, heat-resistant alloys, & difficult-to-machine materials (Ti-based, Ni-based Alloy). Excellent performance especially under unfavorable conditions.

WF15 :

Well balanced physical properties, very good at universal machining of alloyed / non-alloyed steel.Well balanced physical properties, very good at universal machining of alloyed / non-alloyed steel.

K200 :

For stainless steel & heat-resistant alloys machining under work-condition of low cutting speed & high feed rate. Selective submicron carbide grade for optimum tool toughness. |

Fine

K100L :

Certified fine carbide grade for diamond coating tool. For machining graphite, composite material, and high-silicon aluminium alloy.

KR10 :

Fine grain grade specially design for machining Non-ferrous metal, Cast Iron, and Plastic.

|

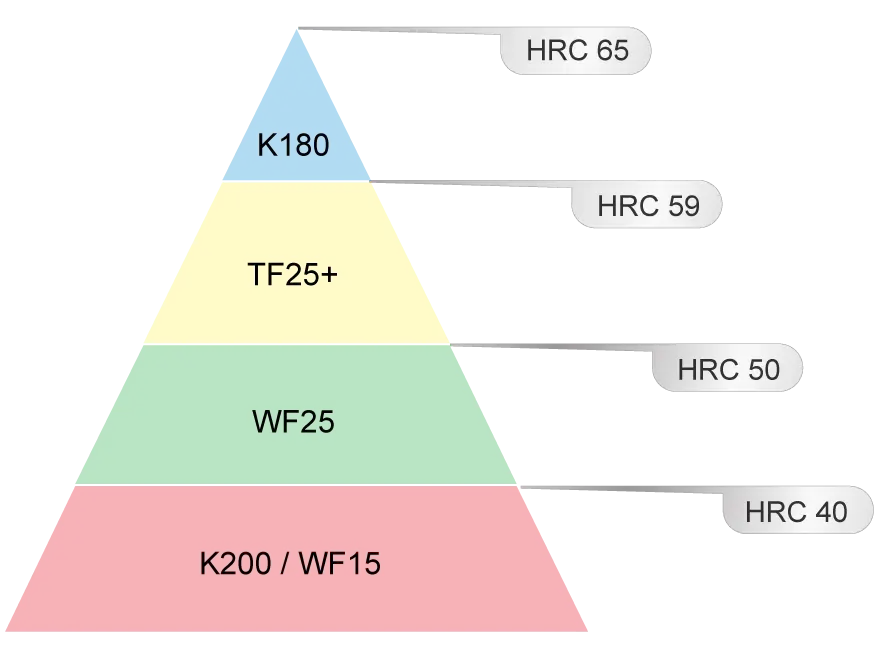

Work Material Hardness Recommendation

Work Material Grade Recommendation

| Work Material | K180 | UF25 | WF25 | KS09 | WF15 | K200 | K100L | KR10 | |

| P | Non Alloy Steel | ○ | ○ | ● | ● | ● | |||

| Low / Medium Alloy Steel | ● | ○ | ○ | ● | ● | ● | ● | ||

| High Alloy Steel | ● | ● | ○ | ● | ○ | ||||

| Ferritic Stainless Steel | ● | ● | ● | ○ | ● | ||||

| Martensitic Stainless Steel | ● | ● | ● | ○ | ● | ||||

| M | Austenitic Stainless Steel | ● | ● | ● | ○ | ● | |||

| Duplex Stainless Steel | ● | ○ | ● | ○ | ● | ||||

| K | Grey Cast Iron | ● | ○ | ○ | ● | ● | ○ | ● | |

| Nodular Cast Iron | ● | ○ | ○ | ● | ● | ○ | ● | ||

| Ductile Cast Iron | ● | ○ | ○ | ● | ● | ○ | ● | ||

| N | Plastic | ● | ○ | ○ | ○ | ○ | ● | ● | |

| Composite Material | ● | ● | |||||||

| Aluminium Alloy (Si<12%) | ● | ○ | ○ | ○ | ○ | ● | |||

| Copper Based Alloy | ● | ○ | ○ | ○ | ○ | ||||

| S | Super Alloy | ● | ● | ● | ○ | ○ | |||

| Titanium Alloy | ● | ○ | ● | ○ | ● | ||||

| H | Harden Steel | ● | ● | ● | ● | ○ | ○ |

● Beat ○ Fit