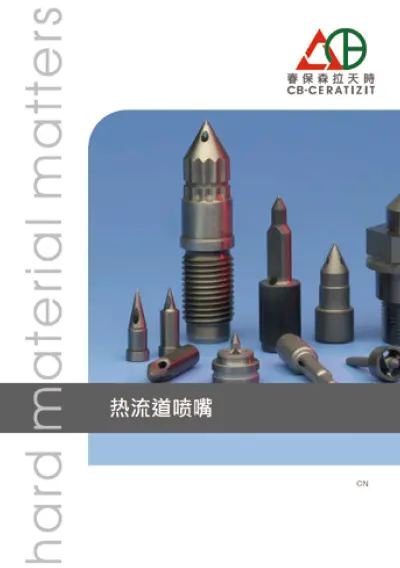

Hot runner nozzle

Excellent wear resistance and thermal conductivity

The continually growing plastics industry benefits from an ever increasing quantity of carbide products, which have all the necessary properties – they are resistant to wear, corrosion and high temperatures, while at the same time conducting heat.

Nozzle Tips Grade Compare

| Grade / Strength | Becu | TZM | Carbide KE25 |

| Conductiong heat | ✔✔✔ | ✔✔ | ✔✔ |

| Wear resistance | ✔ | ✔✔ | ✔✔✔ |

| Corrosion resistance | ✖ | ✔ | ✔✔✔ |

| Application | Normal plastic | Optical fibre plastic | Variety of plastic (

Engineer plastic,

optical fibre, fire-retardant additive and corrosion plastic) |

Your Best Partner--CB CERATIZIT

Professional carbide manufacturer (from powder to finished product)

Dedicated in Finished product, ready to use

Fast delivery, No MOQ, stable quality assurance

Offer complete carbide solution, cost effective

Innovation New Grade---KE25

Optimized thermal conductivity (corrosion resistance) with very high wear resistance| Property | Strength | Your Customer Value |

| Hardness 1000-1500 [HV30] 86.5-91.1 [HRA] |

Wear resistance | Long lifetime Cost savings |

| Thermal conductivity 112-118 [W/m. K] |

Good heat transfer Good flowability |

Process security Long lifetime Cost savings |

| Corrosion resistance | Protection against corrosive attack | Process security Long lifetime Cost savings |

| Themperature resistance (min.800℃:1472°F) |

No effect on material (carbide structure) |

Even hight temperature application are possible |

| Versatile production | Execution according to customer drawing | Product range extendable (New geometries possible) |

● Applications:

○ Hot runner nozzle tips

○ Variety of plastic (Engineer plastic optical fibre,fire-retardant additive and corrosion plastic)

○ Hot runner nozzle tips

○ Variety of plastic (Engineer plastic optical fibre,fire-retardant additive and corrosion plastic)